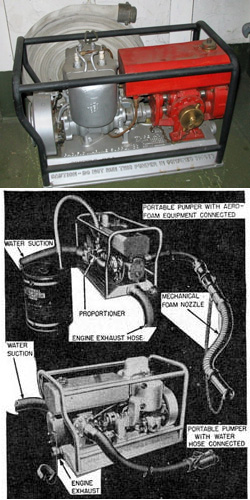

| The P-60 pump, also known as

the handy billy, was developed in 1938 and placed into

service prior to WWII. It was a light-weight, compact

firefighting apparatus complete with rotary-type pump,

driven by a two-cycle, two-cylinder gasoline engine. The

pump, engine, fuel tank, and other necessary accessories

were mounted on a common base. All were enclosed in a

tubular steel frame. The complete unit weighed

approximately 106 pounds and could be handled by one

man. Each unit was equipped with an S-type suction foam

proportioner attached to the suction side, which could

be used with a pick-up tube for producing mechanical

foam. It was provided with three 10-foot lengths of

2-inch suction hose, a suction strainer, one 10-foot

length of 1 ½-inch exhaust hose, one mechanical-foam

nozzle and one Navy pick-up unit (NPU). It was important

that the discharge pressure of the handy billy be

maintained at approximately 100 psi at all times. The

pump was designed to deliver 60 gpm at a discharge

pressure of 100 psi when operating at 3,500 rpm. When

operating at pressures in excess of 100 psi, the engine

speed dropped in proportion to the increase in discharge

pressure; conversely, a decrease in discharge pressure

caused the engine to speed up. Engine speeds in excess

of 4,200 rpm caused serious damage to the engine because

of inadequate cooling and lubrication. Loss of pump

suction caused an increase in the engine speed; unless

stopped immediately, the engine could race at

approximately 7,500 rpm, causing serious damage to the

unit. To avoid further damage, the suction hose had to

be airtight, and the end of the suction hose submerged

at all times. The maximum suction lift to be attempted

with the pump was 20 feet. The engine was lubricated by

means of one pint of No. 2190 oil mixed with the

gasoline; it was never operated without first making

sure that the proper amount of lubricating oil was

thoroughly mixed with the gasoline. The one-gallon

gasoline tank ran the pump for approximately one hour. A

spare two-gallon gasoline can was provided, especially

for rescue and assistance details. The exhaust gases

from the handy billy were cooled by the engine cooling

water, then vaporized and emitted out through the

exhaust with the gases as a vapor. This vapor condensed

upon cooling. Operation of the unit with the exhaust

hose elevated in excess of 4 feet above the engine was

not desirable because the condensed vapors contained in

the exhaust hose created back pressure on the engine

exhaust, which could cause the engine to stop. If the

engine did stop, the column of water in the exhaust hose

would run back through the engine and cause serious

damage to the pump. The handy billy could be operated

below decks if the means were provided to convey the

engine’s toxic exhaust gases to an outside atmosphere

and to separate the condensed vapors from the exhaust

gases. The latter was accomplished by employing an empty

5-gallon sheet metal foam can as a water trap in the

exhaust system. A hole was cut in the side of the can

and a nipple was brazed in this hole of such size that

the 1 ½-inch exhaust hose could slip over the nipple.

The hose was clamped over the nipple with a hose clamp,

and the opposite end of the hose connected to the

engine’s exhaust connection. A similar nipple was brazed

in the top of the can, with an exhaust hose clamped onto

the nipple. The opposite end of the hose was placed in

some spot where the gases were exhausted to the outside

of the vessel. Another hole, ¾- or 1-inch diameter, was

cut in the side of the can, approximately 6 inches above

the bottom, and ¾-inch tubing, formed in the shape of an

L, was brazed in place so one end was approximately ½

inch above the inside bottom of the can. In ship wide or

major emergencies, any member of the ship’s company

could have provided assistance in operating the P-60

pump; otherwise pump teams from repair party lockers

operated the pump. The repair lockers with specific P-60

teams in Condition I were 1, 2, and sometimes 3 and 4,

depending on the ship’s class. This team was also used

in rescue and assistance operations when necessary.

After being operated with sea water, the pump was

flushed and drained with fresh water before being

restored. Pumps were generally stowed in the main deck

passageways near a watertight door, because of the

gasoline tank as well as for quick access, safety and to

reduce saltwater spray corrosion. The P-60 pump began to

be phased out in 1970. It was replaced by the new P-250

pump. |