|

|

|

|

| HOME |

| ABOUT US |

| PARTICIPATE |

| COLLECTIONS |

| DC EQUIPMENT MUSEUM |

| SHIP&SUBMARINE MUSEUM |

| WW II DAMAMGE REPORTS |

| SHIPBOARD CASUALTIES |

| DAMAGE CONTROL MUSEUM |

| DC EQUIPMENT Museum |

| Breathing Apparatus |

| Emergency Fire Hood |

|

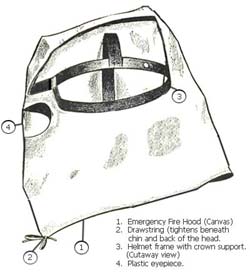

Beginning in the mid 1930s and during WWII, the U.S. Navy

used an improvised protective device called the emergency fire

hood. It was particularly useful for rapid donning in a

smoke-filled compartment. It would, to a limited degree, protect

the wearer from noxious atmospheres for about 3-5 minutes,

depending on the activity of the wearer and the amount of air

entrapped within the hood. The emergency fire hood looked like a bag or sack. It was constructed of light-weight cotton canvas, with a drawstring inserted in a 1-inch double-stitched seam at the bottom. A welder’s helmet-frame was sewn in the top to fit the crown of the head, holding the hood in position. A clear plastic eyepiece was sewn into the hood. The inside was coated with paraffin wax to reduce permeability and improve the air seal fit for the face and head. It was tightened by pulling on the drawstring around the neck and beneath the chin; this was done with caution to avoid choking. The hood did not have any type of filter or supply air cylinder, nor did it scrub the exhaled breath or generate oxygen. Because the wearer would be breathing his own exhaled breath until it was completely depleted of oxygen, he had to be in fresh air before donning the device. After taking and holding a very deep breath, he pulled the hood over his head, tightened the drawstring, exhaled and breathed as slowly as possible to conserve the air in the bag. He then immediately performed the specific task assigned as expeditiously as possible and returned to fresh air. One major problem with wearing the emergency fire hood was losing track of time. Sailors would almost suffocate or be overcome due lack of oxygen. Also, they would get excited and breathe harder, using up their oxygen much faster. As a back-up, other personnel in the repair locker donned regular oxygen cylinder breathers or oxygen breathing apparatus (OBAs); this took longer because they had to activate their canister and get the bags inflated. However, if the emergency fire hood wearer failed to complete the task of securing the cause of a fire, the fire could well become out of control before back-up help was ready. Allowances provided for two emergency hoods each in repair 2, engineering repair 5 and repair 3. They were a self-help item and could be fabricated in the ship’s bos’ns locker onboard or the sail loft ashore. |

|

For more information, see the Index. |